Researching route optimization for electric commercial vehicles

At Mappost, we're currently deep into a research project focused on electric vehicle route optimization in the commercial setting. We've spent the past months gathering requirements from real fleet operators – waste management companies, courier services, other municipal operations – and systematically documenting what companies actually need when planning routes for electric trucks and vans.

We've now compiled ~180 specific requirements and mapped them against current academic research in electric vehicle routing. This research has also allowed us to test common assumptions and myths about electric commercial vehicles against real operational data from multiple industries. Now comes the exciting part: moving from requirements gathering into the algorithmic phase, where we'll evaluate which approaches from scientific literature can solve these real-world problems.

3 Challenges We've Identified In Electric Vehicle Route Optimization

Of all the challenges identified, we have summarized three that we found particularly interesting. These are not exhaustive, but they provide an insight into the complexity of the problem to be solved.

1. Strategic Visibility Matters – Electric Vehicles as Marketing Assets

This one caught us off guard initially, but it makes perfect business sense. Companies are investing hundreds of thousands of euros in electric trucks, and they want to showcase them to the public. Fleet managers specifically want their electric vehicles operating in high-visibility areas – city centers, prestigious neighborhoods, areas with lots of foot traffic.

It's not just about vanity. These companies are making significant green investments, and they want their customers, investors and the general public to see it. A waste collection company wants their electric truck picking up trash in front of the city hall and shopping district, not hidden away in industrial zones. A courier company wants their electric van making deliveries on the main boulevard, where people notice.

But here's the optimization challenge: these high-visibility routes might not naturally be the best fit for electric vehicles from a purely technical standpoint. The algorithm needs to balance operational efficiency with strategic business value. How do you quantify "brand visibility"? How much operational efficiency are you willing to trade for marketing impact?

There's also an economic calculation companies want: show me the actual cost comparison between using an electric truck versus a diesel truck for this specific route. Factor in electricity costs, charging time, diesel prices, and vehicle depreciation. Sometimes the electric option is obviously better, sometimes it's not – but companies want data-driven answers, not assumptions.

This requirement reveals something important: fleet electrification isn't purely a technical or environmental decision. It's a business decision with multiple objectives. The electric vehicle route optimization system needs to factor in that deploying electric vehicles strategically can help justify the investment, win new contracts, satisfy municipal requirements, and improve public perception – all legitimate business goals that should factor into route assignments.

2. Every Truck Is Different And Changes Over Time

Here's something that surprised us: fleet operators don't want to treat all their electric trucks the same way, even if they're the same model. Why? Because batteries degrade differently.

A brand-new electric truck might have a 200 km range. But after two years of intensive use, that same truck might only manage 160 km. An older truck with a degraded battery needs shorter routes – but the traditional approach is to just assign routes randomly or by driver preference, not by the truck's actual current capability.

Fleet managers want the system to track each vehicle's real-world performance over time and automatically adjust route assignments. If Truck A's battery is aging faster than Truck B's, the algorithm should give Truck A the shorter urban routes and Truck B the longer regional ones. And as degradation continues, these assignments should dynamically shift.

But it's not just battery age that matters – it's what the truck is doing. In waste collection, hydraulic systems for lifting containers and compressing waste consume 15-25% of total energy. A route with 200 small bins uses much more hydraulic energy than a route with 50 large containers. The same truck will have completely different effective ranges depending on the type of work.

Adding another layer of complexity: seasonal variations aren't as simple as "winter equals shorter range." Yes, cold weather reduces battery performance. But in waste collection, summer can actually be more demanding – higher waste volumes mean more containers to service, which means the hydraulic systems work harder. Factor in air conditioning for the driver during hot weather, and suddenly the summer energy equation becomes just as complex as winter's. The optimization needs to account for these seasonal operational patterns, not just temperature effects on batteries.

Of course, electric trucks have inherently more limited range compared to diesel vehicles, which makes careful route evaluation critical. This means route planning can't just be about distance – it needs to account for how many clients are planned today, what type, how heavy is the load, what's the truck's current battery health, what's the weather forecast, what's the seasonal demand pattern? All these factors combine to determine what's actually feasible for each specific truck on each specific day, and which routes are genuinely suitable for electric vehicles versus requiring diesel.

This level of individualization is completely foreign to traditional fleet management, where diesel trucks are largely interchangeable. But with electric vehicles, treating them as identical when they're not leads to either range anxiety (being too conservative) or operational failures (being too optimistic).

One critical insight from our research: it's not kilometers or even industry sector that determines EV suitability – it's the route character itself. Urban routes with frequent stops can see 60-80% energy recovery through regenerative braking, while regional routes with long distances between stops recover only 20-30%. This fundamental asymmetry means the same vehicle performing brilliantly in city center waste collection might struggle on rural routes half the distance.

3. Charging Takes Time Changes Planning

One of the biggest planning challenges with electric fleets is the time it takes to charge. When you have 3-5 electric trucks that all need charging, and each charge takes hours rather than minutes, your entire operational routine needs to be rethought.

Fleet managers told us they need systems that can automatically figure out the charging sequence based on tomorrow's routes and the available charging slots at the depot. If you only have two charging points but five trucks, which one charges first? Which truck should leave first in the morning while others are still charging? How do you rotate them through the chargers efficiently?

For courier operations, there's another dimension: can we synchronize charging with lunch breaks or rest periods? If a driver needs to charge for 45 minutes and they're due for a 30-minute lunch break, the optimization should find a charging station near a good lunch spot or a cluster of deliveries they can make on foot. The goal of electric vehicle route optimization is turning unavoidable waiting time into productive time – or at least less frustrating time.

Most companies also will want to maximize charging at their own depot where electricity is cheaper, rather than using expensive public fast-charging stations. But that requires careful route planning to ensure trucks can always make it back to base, or knowing exactly when a mid-route charge is unavoidable and worth the cost.

What we've learned from operator experience: approximately 90% of commercial EVs never use public charging infrastructure – they rely entirely on overnight charging at base. This changes the infrastructure conversation significantly.

The complexity here isn't just mathematical – it's operational. Charging constraints ripple through every aspect of fleet management and traditional routing algorithms simply weren't designed for this.

Why This Research Matters

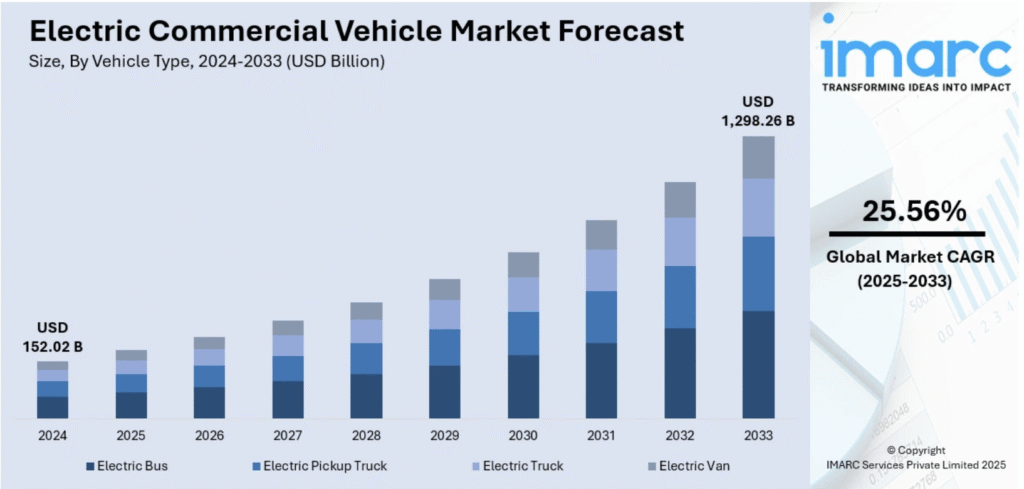

Electric commercial vehicles are growing rapidly – the market is expected to grow from $152 billion (2024) to $1.3 trillion by 2033. EU regulations are driving this transition, mandating 45% CO₂ reduction by 2030 and 90% by 2040 for new heavy vehicles.

But electric commercial vehicles can't simply follow the same planning approaches as diesel trucks. The constraints are fundamentally different: limited range, long charging times, developing infrastructure, and complex energy consumption patterns. Companies investing in electric fleets need intelligent systems that understand these differences and can optimize accordingly.

Where We Go From Here

We're now moving into evaluating which optimization algorithms from academic literature can address these practical challenges. Some problems have promising theoretical solutions; others will require new approaches or adaptations. Stay tuned for the next updates!

Our collaboration with the University of Latvia's Institute of Mathematics and Computer Science brings together practical logistics experience with rigorous scientific methodology. The goal is creating tools that help companies identify optimal routes for their electric vehicles, plan efficient charging schedules, balance mixed fleets, and maximize both operational efficiency and environmental impact.

The project is co-financed by the Recovery Fund under the Operational Programme "Latvia's Recovery and Resilience Mechanism Plan 1.2. Reform and Investment Direction 'Energy Efficiency Improvement' 1.2.1.2.i. Investment 'Increasing Energy Efficiency in Entrepreneurship (including transition to renewable energy technology use in heat supply and research and development activities (including in bioeconomy))' 1.2.1.2.i.2. measure 'Development of Innovative Products and Technologies'. Read more about it here.

Please select the most suitable time for a call with Mappost representative

We will be happy to share more about Mappost, demonstrate the system and answer all your questions!